State-of-the-art Machinery. Innovative Materials. Lean Manufacturing Principles.

At Tetro, we handle all manufacturing processes in-house to ensure quality, production continuity, and fast cycle-times.

We offer the full set of technologies and tailor the most intelligent and efficient way to deliver more value faster.

PLASTIC

The Thermoplastic Difference

Our world-class thermoplastic facility offers the full spectrum of technologies and materials to

develop lightweight products with enhanced performance and circularity. With a clear focus on

solving industry challenges such as weight reduction, durability, and carbon footprint, we

leverage material science to redefine weight and performance for any industry and applications.

100% Recyclable

& Reusable

Low

Emission

Production

Design

Flexibility

Lightweight

Superior

Mechanical

Properties

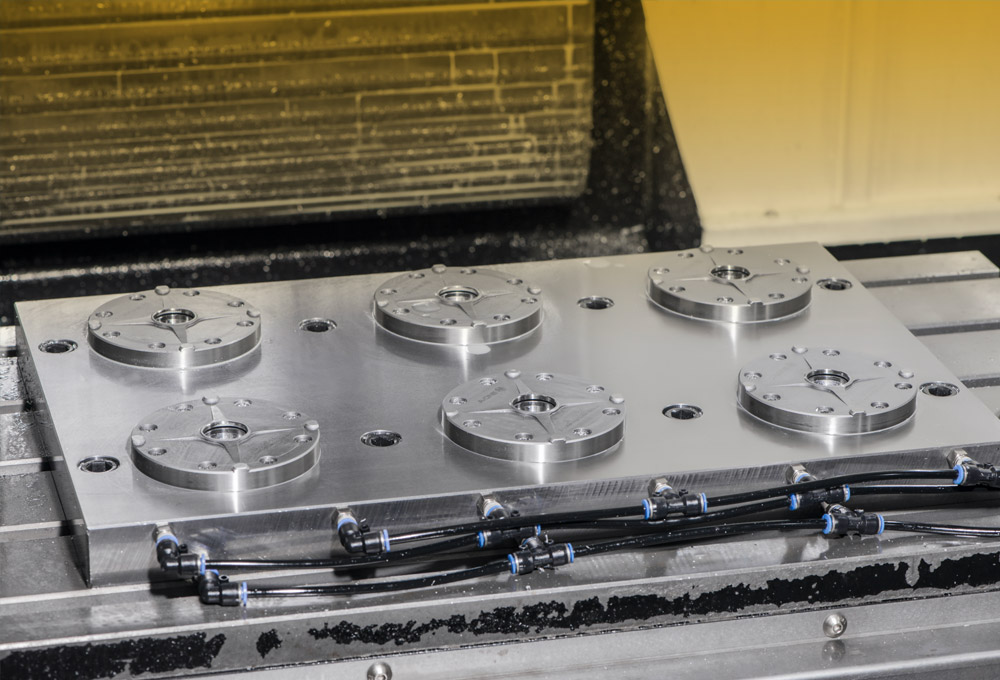

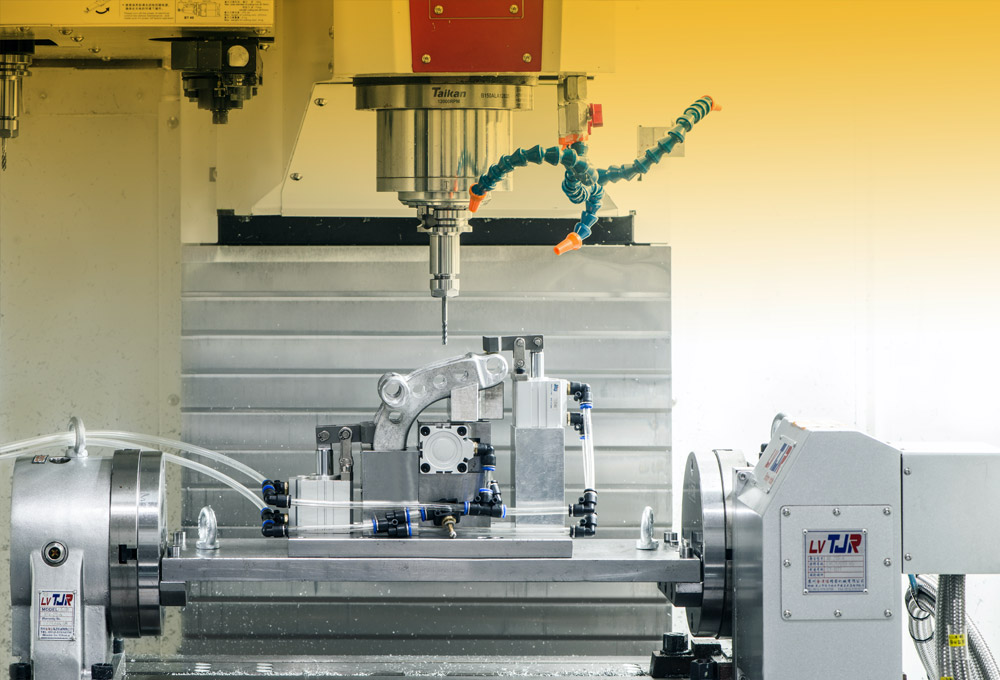

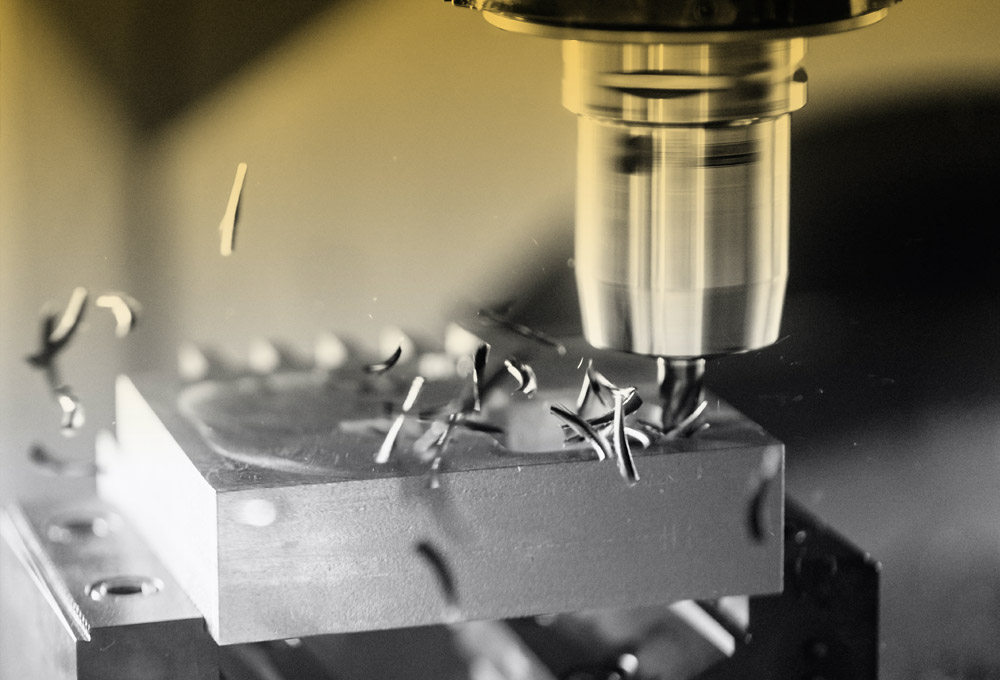

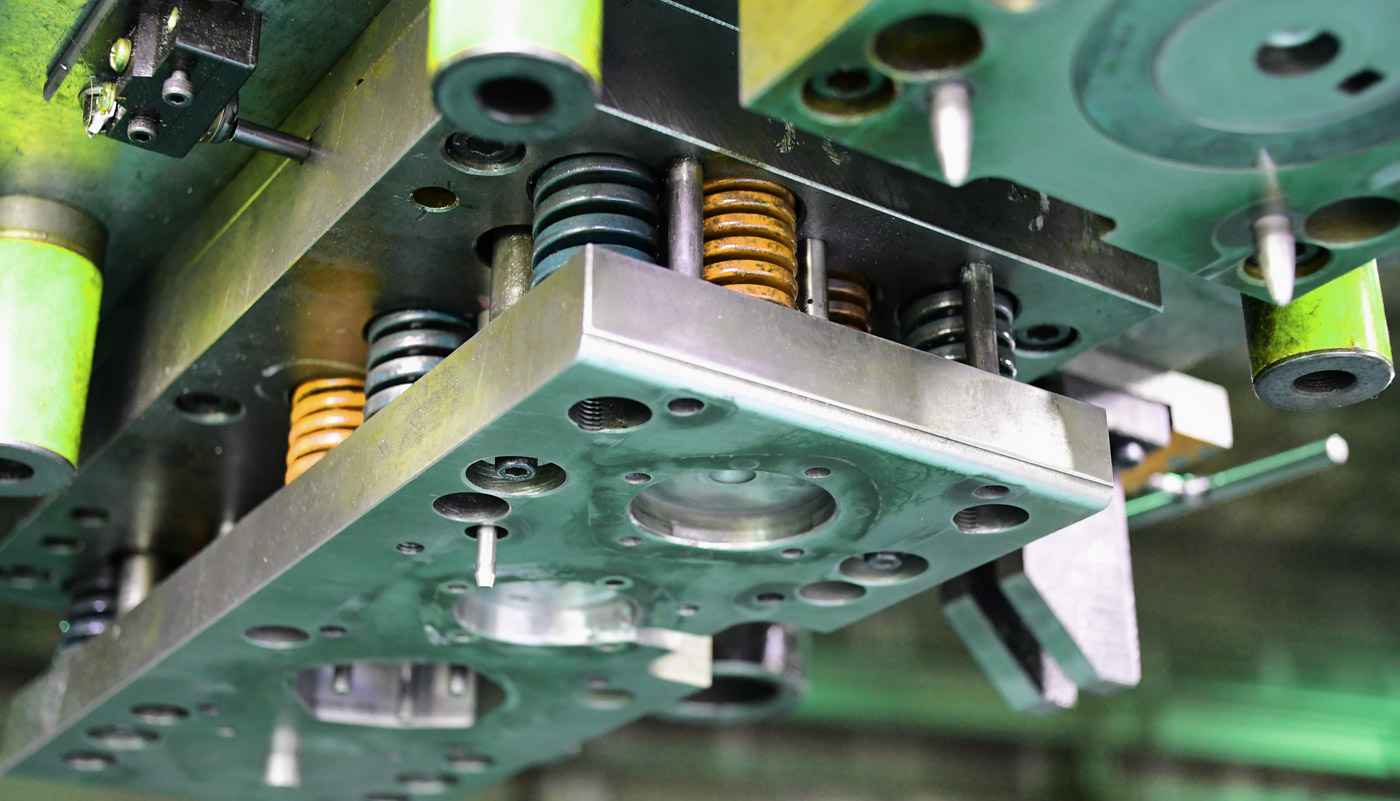

Mold Making &

Precision Tooling

Plastic molding and tooling have a significant impact on final product quality, cost, and waste. As a critical step of the product development process, we design and manufacture our molds at our facilities.

Through close collaboration between R&D teams, mold designers, and tool builders, we deliver an immediate response to troubleshooting and optimize production cycles and material utilization.

Using the latest tooling technologies and industry standards, we ensure accurate, repeatable part production for any thermoplastic application.

Compression

Molding

A variety of compression molding technologies, suitable for a wide range of industrial, commercial, and consumer products ranging from the smallest parts to automotive panels.

Committed to manufacturing responsibly, we continue to expand our compression molding abilities, particularly in terms of automation and energy efficiency.

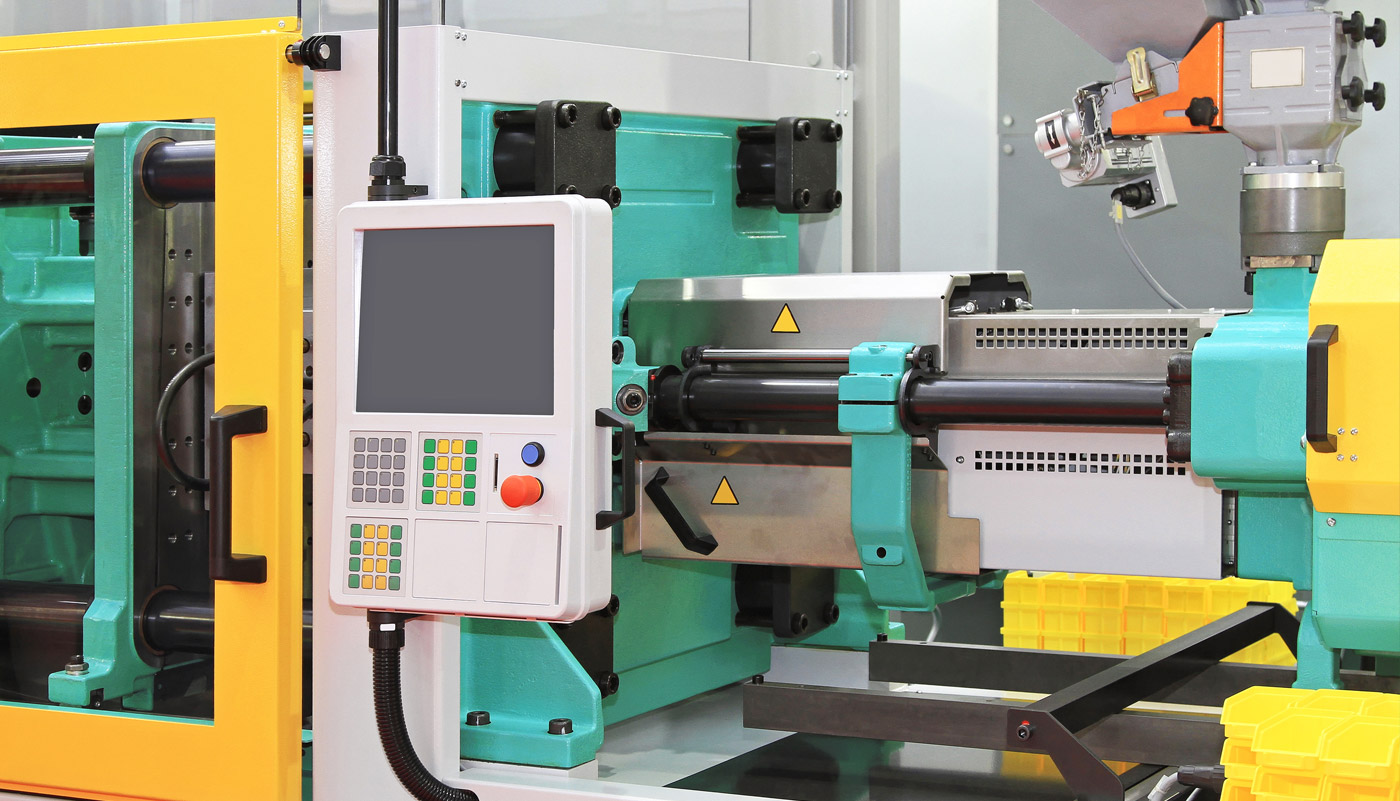

Injection Molding

Best-in-class molding capabilities, a robust experienced team, and highly monitored processes enable us to deliver high quality parts quickly and efficiently.

We offer a wide range of materials and finishes and the latest technologies, including insert molding, overmolding, and complex material combinations.

With capacities ranging from 50 to 1000 tons, our injection machines are made by the most trusted manufacturers in the industry, such as Nissei, Arburg and Demag.

Our in-house capabilities

- 70 Injection machines

- Double component injection

- Gas-assisted injection

- In-mould labelling (IML)

- Central Dosing System

- Central secondary cooling system

- Energy saving systems

- Automation Robots

- Magnetic pallets

Game-changing Engineered Thermoplastic

Particle Foam

Tetro opens a new world of opportunities for particle foam applications.

Dedicated to overcoming particle foam's design limitations and energy intensity, we've developed innovative technologies that optimize surface finish in a sustainable way. Our solutions offer great suspension, energy absorption, and isolation with enhanced visual appearance and a selection of look and feel surfaces.

Committed to sustainability, our energy-efficient particle foam facility generates zero waste and offers groundbreaking end-of-life solutions.

Our in-house capabilities

- Thermo-select (TS)

- Radio Frequency (RF)

- Polymeric Hybrid Structure (PHS) – Patent Pending

Continious Fiber

Thermoplastic

From laminates and profiles to complex 3D structures, we offer a lightweight, high-performance alternative for metal, wood, and thermosetting polymers.

With our novel weaving systems, we combine the mechanical properties of glass/carbon continuous fiber reinforcement with the design flexibility of thermoplastic matrices without compromising on aesthetics and quality.

Our in-house capabilities

- Braiding

- Tailor Fabric Placing (TFP)

TEXTILE

High Performance with Beautiful Appeal

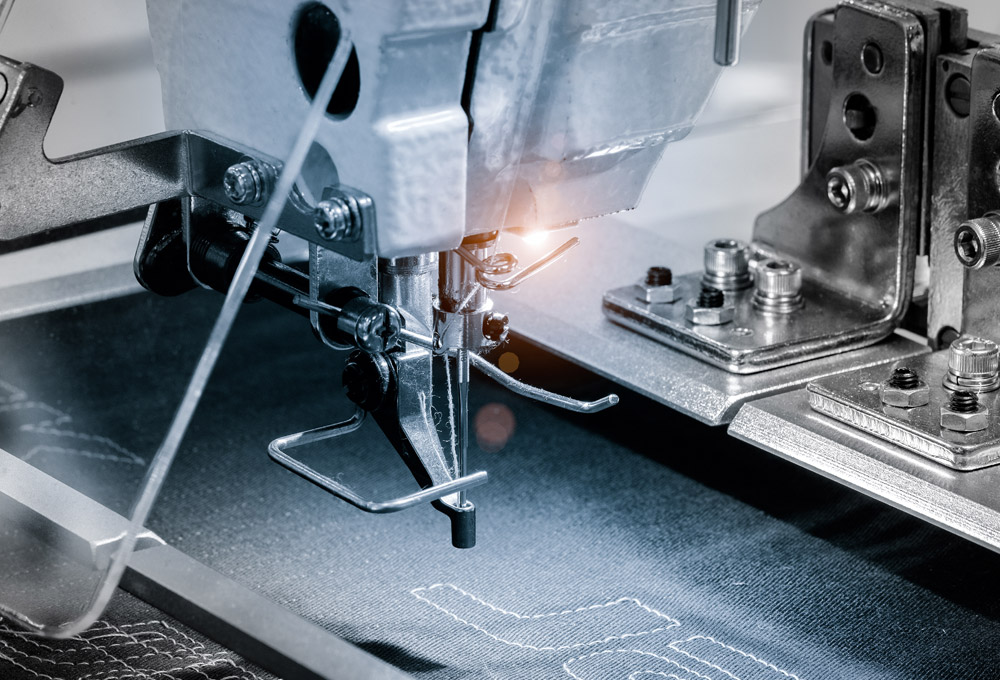

The Starry Group has over 20 years of experience as a leading manufacturer of technical textiles for global brands. Our textile facility, Neostar, was established in 2011 and specializes in precision industrial sewing with more than 500 electronic sewing machines.

Our in-house capabilities

- Heat-transfer printing & embroidery

- High-frequency & ultrasonic welding

- Thermoforming & hot press molding

- Laser cutting & lamination

- Bonding technology with vacuum positioning

- Computerized sewing

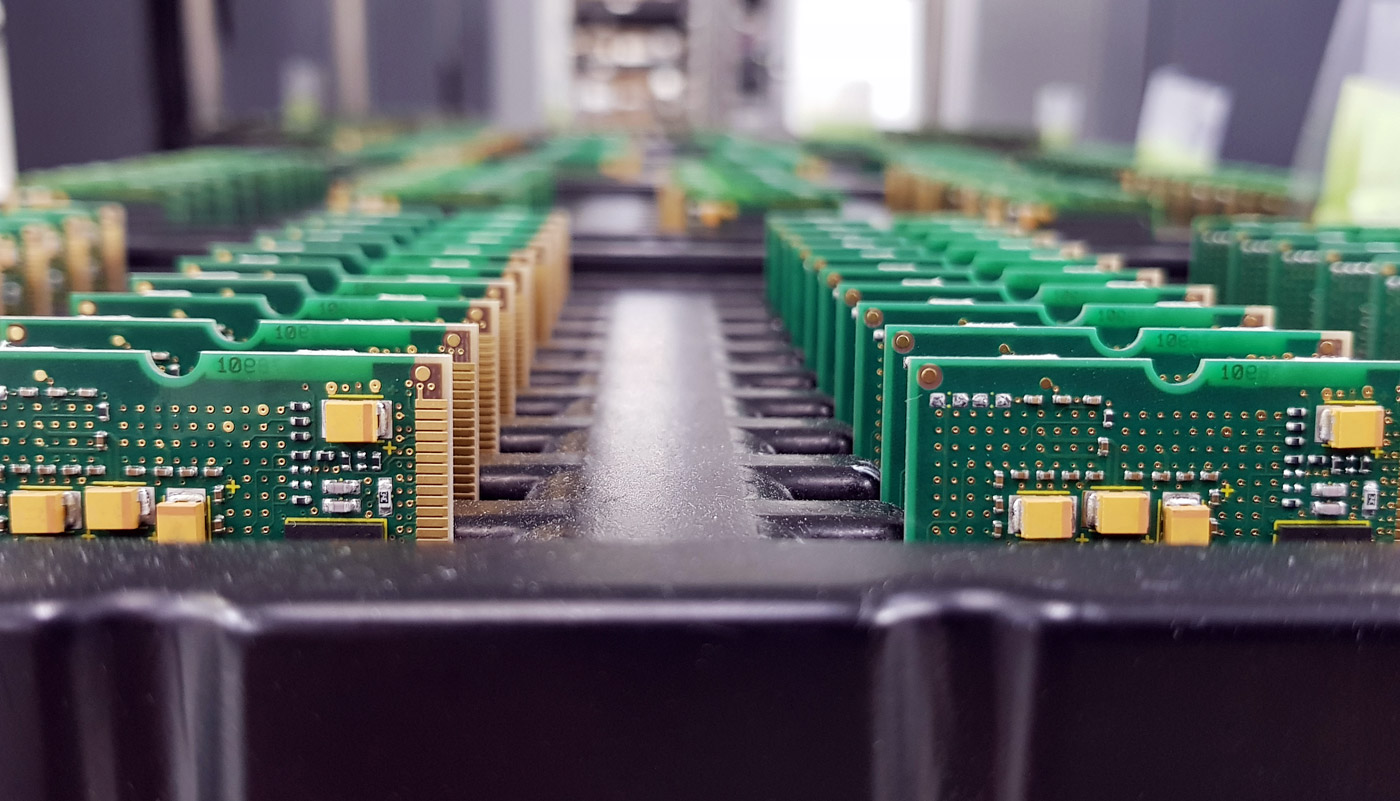

ELECTRONICS

Design Products for the Future

We offer advanced electronic component integration to meet the growing demand for smart products.

Through our partners, we implement IoT electronics, online tracking systems, and advanced monitoring systems that enhance products with innovation and connectivity.

Our Partners