Streamline

Product Development

From concept to mass production

R&D

Customer’s

Full Development

Kit

Robust engineering capabilities that turn initial product design, drawings, and specifications made by the customer, into an intelligent and efficient plan for serial production at any scale.

Tetro’s R&D

Support

Working together with our customers, complementing their product design and engineering needs in a transparent collaborative workflow. With the support of our international R&D teams, we simplify product development and enable unique access to cutting-edge technologies and proprietary know-how that differentiate products from the competition.

Tetro’s A to Z

Full Development

Support

Tetro’s single source solution for product design and development from end-to-end. With experience in material selection, prototyping, testing, and scale up, we are trusted by leading brands globally to take full product responsibility from start to finish.

Prototyping

Workshop

Interdisciplinary workshop specializing in developing high quality prototypes with efficiency and accuracy. With a “design for manufacture” perspective, our engineers work closely with our customers to improve design, user experience, and mechanical performance from proof-of-concept to golden samples.

Equipped with the latest technologies and tools, such as simulation platforms, 3D printers, mini molding machines, and an archive room, our workshop has successfully produced thousands of samples for well-known brands.

Lab

World class in-house laboratory that ensures consistent high product quality of our raw materials and finished products.

From physical testing and working side by side with our Quality Assurance and compliance departments to researching new materials, our advanced lab is an integral part of our product development process.

Our in-house capabilities

- Aging machine

- Tensile machine

- Impact machine

- MFI tester

- Heavy metal XRF analyzer

- Hydrogen embrittlement tester

- Water-repalletizing tester

- Spring Lifetime tester machine

- Cord lifetime tester

- Running machine

- Drum test machine

- Vickers hardness tester

- Drop tester

- Carton edge tester

- Sample room

Support Systems

Digital Deveoplement Journey

Our product development process is supported by automation, IoT, and digital platforms to intelligently manage

capital, time, resources, and environmental impact with full visibility and control.

MANAGEMENT

Basecamp Project Management

Teamgantt Gantt Charts

Composer - SolidWorks

Mastercam - SolidWorks CAD Files Database

REPORTING

Matics

IoT - RTS SYSTEM

Energy Consumption Monitoring

and Statistics Model

MANUFACTURING

Kitaron System

ERP Enterprise Resource System

QMS Quality Management System

MES Real-Time Production System

Microsoft Power BI Business data analytics

SolidWorks PDM Product Data Management

SolidWorks

SolidWorks Simulations

Computerized Statistical

Custom Tools to manage our

SolidWorks data (BOM)

Moldex

Ansys

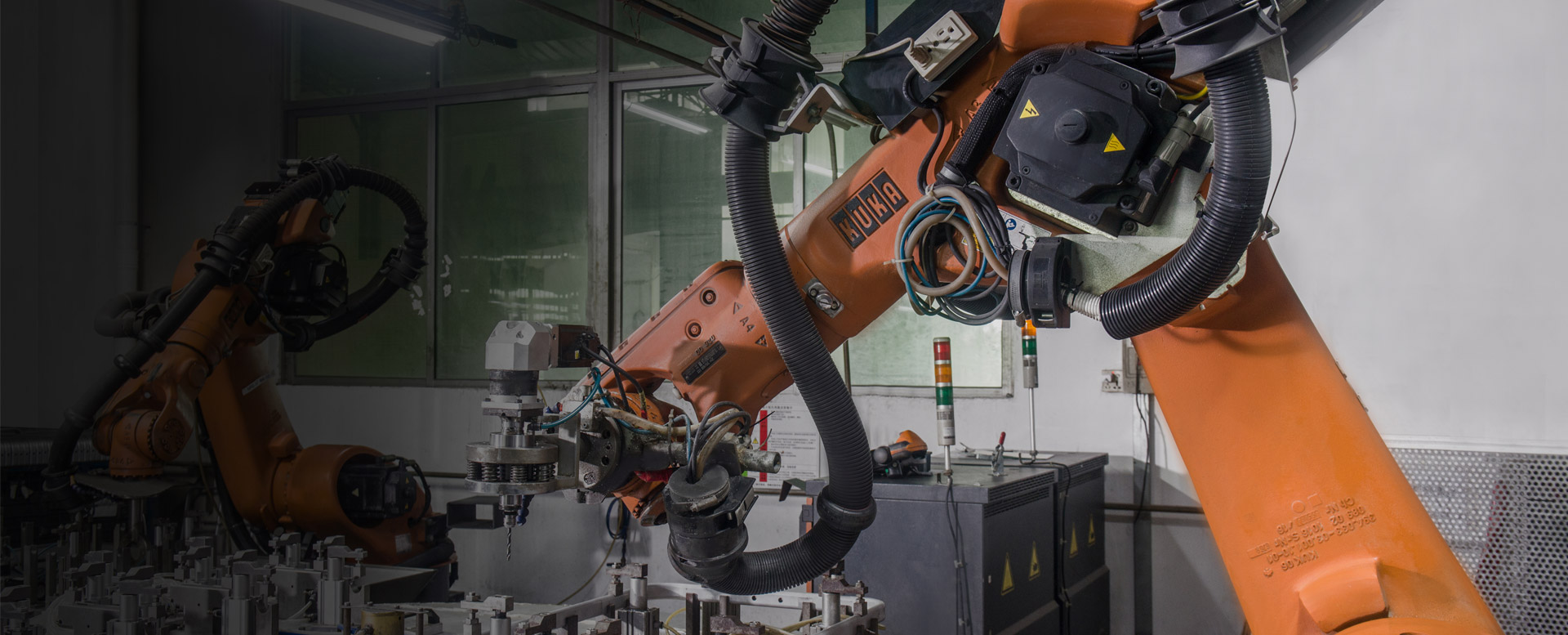

Production

State-of-the-art manufacturing facility integrating plastic, metal, textile, and electronics departments working in full synergy. Our +100 sqm production site features an extensive selection of materials and technologies, advanced machinery, and industry 4.0 tools at the highest international standards.

We invest heavily in expanding our technological capabilities and developing low-energy manufacturing processes that promote a net-zero future.

Assembly Lines

With over 13 assembly lines, we are delivering a one-piece flow with a clear focus on quality, precision, and efficiency. Along with the 6s methodology, we tailor the assembly process to customers’ requirements and safely achieve fulfillment on time every time.